In the world of panel cutting, efficiency and precision are critical, and HUAHUA CNC’s advanced panel saw technology delivers just that. A key feature of this machine is the independent lifting capability for both large and small saws, which provides enhanced flexibility for cutting different panel sizes and thicknesses. This system, along with the automatic adjustments for board thickness, makes the HUAHUA CNC panel saw a cutting-edge solution for manufacturers looking to streamline their operations. Combined with the newly optimized countertop and lift table, this technology sets a new standard in the CNC industry.

Independent Lifting of Large and Small Saws

One of the standout features of the HUAHUA CNC panel saw is the ability to independently lift large and small saws. This capability allows for increased flexibility in handling various panel sizes and thicknesses. The system automatically adjusts the sawing stroke according to the thickness of the board, minimizing idle time and ensuring a smoother cutting operation. With a saw base speed of up to 120m/min, this feature helps boost cutting efficiency, saving both time and resources.

Optimized Countertop and Lift Table Features

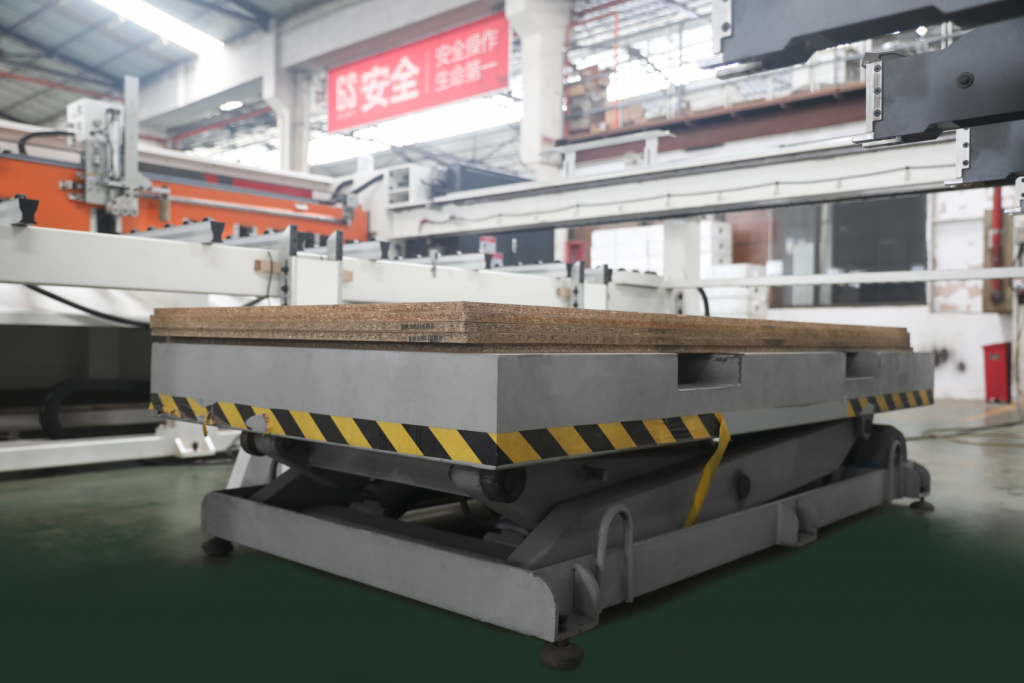

The CNC panel saw by HUAHUA CNC also includes a redesigned countertop that significantly reduces edge bursting, thanks to its narrower width. The table’s 25mm thickness ensures durability and prevents deformation over time, while the 8m3 air-floating table with roller-assisted cutting provides a smoother surface for workpieces. The lifting platform is another advanced feature, automatically loading materials with infrared ray sensing technology to ensure precise alignment, further enhancing cutting accuracy and quality.

Conclusion

HUAHUA CNC continues to innovate in the CNC panel saw market, offering solutions that prioritize efficiency, precision, and ease of use.